Silicon Carbide Wafer Market Overview:

1. Introduction to Silicon Carbide (SiC) Wafers:

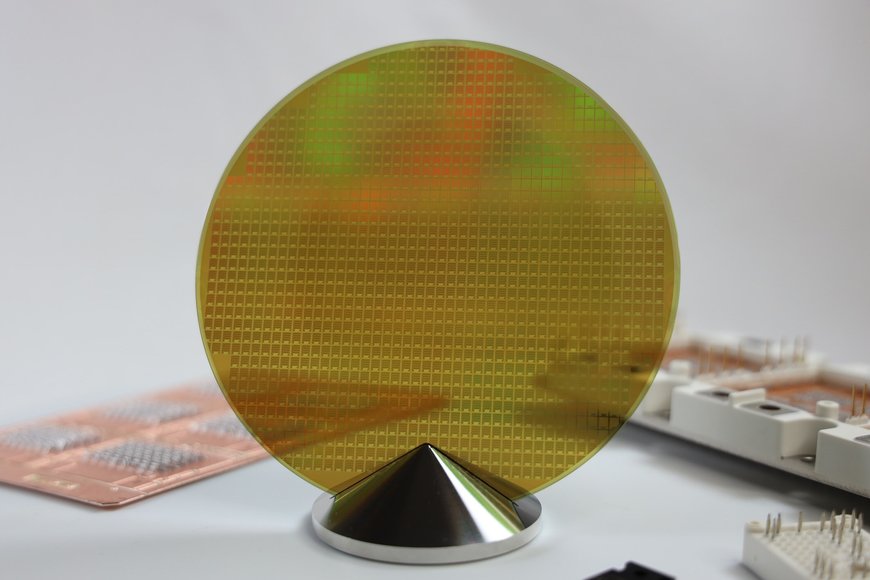

- Silicon Carbide Wafers serve as a critical component in the semiconductor industry.

- SiC is a wide-bandgap semiconductor material known for its superior thermal conductivity, high-temperature stability, and resistance to harsh environmental conditions.

2. Growth Drivers:

- Power Electronics: SiC wafers are integral to power electronics applications, enabling high-efficiency power devices for electric vehicles, renewable energy systems, and industrial applications.

- 5G Technology: The demand for SiC wafers is driven by their suitability for high-frequency, high-power 5G applications.

- Automotive Industry: The shift towards electric vehicles and advancements in automotive electronics contribute to the growing demand for SiC wafers.

3. Applications:

- Power Devices: SiC wafers are extensively used in manufacturing power devices such as MOSFETs and Schottky diodes for efficient power management.

- RF and Microwave Devices: The high-frequency capabilities of SiC make it suitable for RF and microwave devices in communication systems.

- Optoelectronics: SiC wafers find applications in the production of UV and blue LEDs and advanced photodetectors.

4. Manufacturing Processes:

- CVD and Epitaxy: Chemical Vapor Deposition (CVD) and epitaxial growth processes are commonly used for SiC wafer production, ensuring high crystal quality.

- Wafer Dicing: After growth, wafers undergo precision dicing processes to achieve desired sizes for semiconductor device fabrication.

5. Market Challenges:

- High Production Costs: The manufacturing of high-quality SiC wafers involves complex processes, contributing to relatively high production costs.

- Supply Chain Constraints: The SiC wafer market may face challenges related to the supply chain, especially in ensuring a consistent and reliable source of raw materials.

Silicon Carbide Wafer Market Size and Trends:

1. Market Size:

- The Silicon Carbide Wafer market has witnessed significant growth, driven by the increasing adoption of SiC-based power devices.

- Market expansion is notable in regions with a strong focus on electric vehicles, renewable energy, and high-frequency applications.

2. Industry Trends:

- Focus on Wide-Bandgap Semiconductors: The industry is witnessing a shift towards wide-bandgap semiconductors, with SiC leading the way.

- Collaborations and Partnerships: Companies are engaging in collaborations to enhance production capabilities and accelerate the development of SiC-based technologies.

Receive the FREE Sample Report of Silicon Carbide Wafer and Polishing Pad Market Research Insights @ https://stringentdatalytics.com/sample-request/silicon-carbide-wafer-and-polishing-pad-market/7853/

Market Segmentations:

Global Silicon Carbide Wafer and Polishing Pad Market: By Company

• Wolfspeed

• SK Siltron

• SiCrystal

• II-VI Advanced Materials

• Showa Denko

• Norstel

• TankeBlue

• SICC

• Hebei Synlight Crystal

• CETC

• DuPont

• Cabot

• FUJIBO

Global Silicon Carbide Wafer and Polishing Pad Market: By Type

• Silicon Carbide Wafer

• Silicon Carbide Wafer Polishing Pad

Global Silicon Carbide Wafer and Polishing Pad Market: By Application

• Power Device

• Electronics & Optoelectronics

• Wireless Infrastructure

• Others

Regional Analysis of Global Silicon Carbide Wafer and Polishing Pad Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Silicon Carbide Wafer and Polishing Pad market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Silicon Carbide Wafer and Polishing Pad Market Research Report @ https://stringentdatalytics.com/purchase/silicon-carbide-wafer-and-polishing-pad-market/7853/

Silicon Carbide Polishing Pad Market Overview:

1. Introduction to Polishing Pads:

- Polishing pads are crucial in the semiconductor manufacturing process, facilitating the planarization and polishing of wafer surfaces.

- Silicon Carbide Polishing Pads are known for their durability, abrasion resistance, and efficiency in achieving precise surface finishes.

2. Growth Drivers:

- Rising Semiconductor Demand: The increasing demand for semiconductors, driven by various industries, fuels the demand for efficient polishing solutions.

- Advancements in Semiconductor Technology: As semiconductor manufacturing processes evolve, there is a growing need for polishing pads that can meet the requirements of advanced technologies.

3. Applications:

- Wafer Planarization: Silicon Carbide Polishing Pads play a critical role in the planarization process, ensuring a smooth and flat surface for subsequent semiconductor device fabrication steps.

- CMP (Chemical Mechanical Planarization): CMP processes rely on polishing pads to remove excess material and achieve precise layer thickness.

4. Manufacturing Materials and Techniques:

- Material Composition: Silicon Carbide Polishing Pads are often made using a combination of silicon carbide particles and a polymer matrix.

- Structural Design: The design of the polishing pad structure, including the arrangement and size of abrasive particles, influences its effectiveness in planarization.

5. Market Challenges:

- Pad Lifespan and Consistency: Ensuring consistent performance and a prolonged lifespan of polishing pads is crucial for semiconductor manufacturing efficiency.

- Compatibility with New Materials: With the introduction of new materials in semiconductor manufacturing, adapting polishing pads to be compatible with these materials poses a challenge.

Silicon Carbide Polishing Pad Market Size and Trends:

1. Market Size:

- The Silicon Carbide Polishing Pad market is experiencing growth in tandem with the expanding semiconductor industry.

- Increasing investments in research and development contribute to the innovation and enhancement of polishing pad technologies.

2. Industry Trends:

- Focus on Sustainability: There is a growing emphasis on developing environmentally sustainable polishing pad materials and manufacturing processes.

- Customization for Advanced Materials: Companies are customizing polishing pads to meet the specific requirements of advanced semiconductor materials, such as SiC wafers.

Conclusion:

In conclusion, the Silicon Carbide Wafer and Polishing Pad markets are integral components of the semiconductor industry, contributing to the advancement of power electronics, high-frequency applications, and cutting-edge semiconductor technologies. The growth of these markets is closely tied to the increasing demand for efficient semiconductor devices in sectors such as electric vehicles, 5G technology, and renewable energy. Continuous innovation in manufacturing processes, collaborations, and a focus on sustainability are key trends shaping the present and future of these markets.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

Leave a Reply