Mass Flow Controllers (MFCs) are critical components in semiconductor manufacturing. They precisely regulate the flow of gases and liquids in processes like chemical vapor deposition (CVD), etching, and doping. The semiconductor mass flow controller market is driven by advancements in semiconductor technology, increasing complexity in chip design, and the growing demand for high-performance electronic devices.

Overview Analysis

Mass Flow Controllers (MFCs) play a vital role in ensuring the precise and accurate flow of gases and liquids, essential for maintaining the quality and efficiency of semiconductor manufacturing processes. These controllers are used in various steps, including deposition, etching, and lithography, contributing to the overall yield and performance of semiconductor devices.

Market Size and Growth

- 2023 Market Value: Approximately USD 1.5 billion.

- Growth Rate: Expected CAGR of 7-9% from 2024 to 2030.

- Projected Market Value: Around USD 2.7 billion by 2030.

Key Applications

- Chemical Vapor Deposition (CVD): MFCs regulate the flow of precursor gases, crucial for depositing thin films on wafers.

- Etching: Used to control the flow of etchants in processes that define the intricate patterns on semiconductor wafers.

- Doping: Ensure precise flow of dopant gases in the doping process, essential for modifying electrical properties of semiconductors.

Trends

- Advancements in Semiconductor Technologies:

- Miniaturization: Increasing demand for smaller and more powerful semiconductor devices drives the need for MFCs capable of handling ultra-low flow rates with high precision.

- 3D Integration: Adoption of 3D semiconductor technologies such as 3D NAND and TSV (Through-Silicon Via) requires advanced MFCs to manage complex gas flows accurately.

- Smart Manufacturing and Automation:

- Integration with IoT: MFCs integrated with IoT for real-time monitoring and control enhance process efficiency and reliability.

- AI and Machine Learning: Use of AI and machine learning to optimize flow control and predict maintenance needs, leading to reduced downtime and increased productivity.

- Sustainability and Eco-Friendly Practices:

- Green Manufacturing: Emphasis on reducing greenhouse gas emissions and toxic waste in semiconductor manufacturing increases demand for MFCs with eco-friendly features.

- Energy Efficiency: Development of energy-efficient MFCs to reduce power consumption in manufacturing processes.

- Customization and Flexibility:

- Modular Designs: Growing trend towards modular MFCs that can be easily adapted to different manufacturing processes and requirements.

- Custom Solutions: Increasing demand for custom-engineered MFCs tailored to specific process needs and client specifications.

Opportunities

- Expansion in Semiconductor Manufacturing:

- Increased Capacity: Expansion of semiconductor fabrication facilities worldwide to meet rising demand for electronic devices creates significant opportunities for MFC suppliers.

- Emerging Markets: Growth in semiconductor manufacturing activities in regions like Asia-Pacific, particularly China and Taiwan, presents new market opportunities.

- Technological Innovations:

- Advanced Materials: Development of MFCs using advanced materials for improved performance, such as enhanced corrosion resistance and thermal stability.

- Micro and Nano Flow Control: Opportunities in the development of MFCs capable of handling micro and nano flow rates for advanced semiconductor processes.

- High-Performance and Precision Applications:

- High-Precision Manufacturing: Demand for high-precision MFCs in applications requiring extremely tight tolerances, such as EUV (Extreme Ultraviolet) lithography and advanced packaging.

- Advanced Sensors: Integration of advanced sensors in MFCs for real-time flow measurement and control, improving accuracy and process stability.

- New Industry Applications:

- Photonics and Quantum Computing: Emerging applications in photonics and quantum computing drive the need for precise and reliable MFCs.

- Biomedical Devices: Increasing use of semiconductors in biomedical devices and diagnostics presents opportunities for MFCs in non-traditional sectors.

Key Growth Drivers

- Rising Demand for Semiconductors:

- Consumer Electronics: Growing demand for consumer electronics, including smartphones, tablets, and wearable devices, drives the need for advanced semiconductor manufacturing and MFCs.

- Automotive Electronics: Expansion in automotive electronics, particularly with the rise of electric and autonomous vehicles, fuels the demand for high-performance semiconductors and MFCs.

- Technological Advancements:

- Precision Control: Innovations in precision control technologies enhance the performance and reliability of MFCs, supporting the production of advanced semiconductor devices.

- Advanced Manufacturing Processes: Adoption of advanced manufacturing processes, such as atomic layer deposition (ALD) and chemical mechanical planarization (CMP), increases the demand for sophisticated MFCs.

- Sustainability Initiatives:

- Environmental Regulations: Stricter environmental regulations drive the development of MFCs that minimize emissions and waste, promoting greener manufacturing practices.

- Energy Efficiency: Focus on energy-efficient solutions in semiconductor manufacturing supports the growth of MFCs with low power consumption and high efficiency.

- Market Expansion:

- Geographical Growth: Expansion of semiconductor manufacturing facilities in emerging markets, particularly in Asia-Pacific and Latin America, creates new opportunities for MFC providers.

- Industry Diversification: Increasing applications of semiconductors in diverse industries, such as healthcare, automotive, and telecommunications, expand the market for MFCs.

Development and Forecasts

- Product Development:

- Enhanced Performance: Development of MFCs with enhanced performance characteristics, including improved accuracy, response time, and flow stability.

- Integration of Advanced Technologies: Incorporation of advanced technologies such as digital control, AI, and IoT to enhance the functionality and reliability of MFCs.

- Market Expansion:

- Emerging Markets: Focus on expanding market presence in emerging regions with growing semiconductor manufacturing activities.

- Strategic Partnerships: Formation of strategic partnerships with semiconductor equipment manufacturers to integrate MFCs into advanced fabrication tools.

- Technological Integration:

- AI and Data Analytics: Use of AI and data analytics for predictive maintenance, optimizing flow control, and enhancing process efficiency.

- Real-Time Monitoring: Development of MFCs with real-time monitoring capabilities to provide continuous feedback and control during semiconductor manufacturing.

- Forecasts:

- Market Growth: The MFC market is expected to grow at a CAGR of 7-9% from 2024 to 2030.

- Technological Advancements: Continued advancements in semiconductor technology and manufacturing processes will drive market growth and innovation in MFC design and functionality.

- Sustainability Focus: Increasing focus on sustainability and energy efficiency will shape market trends and development strategies.

Receive the FREE Sample Report of Semiconductor Mass Flow Controller Market Research Insights @ https://stringentdatalytics.com/sample-request/semiconductor-mass-flow-controller-market/9810/

Market Segmentations:

Global Semiconductor Mass Flow Controller Market: By Company

• HORIBA

• Fujikin

• MKS Instruments

• Sevenstar

• Hitachi Metals, Ltd

• Pivotal Systems

• MKP

• AZBIL

• Bronkhorst

• Lintec

• Kofloc

• Brooks

• Sensirion

• ACCU

• Sierra Instruments

Global Semiconductor Mass Flow Controller Market: By Type

• Thermal Type

• Pressure Type

Global Semiconductor Mass Flow Controller Market: By Application

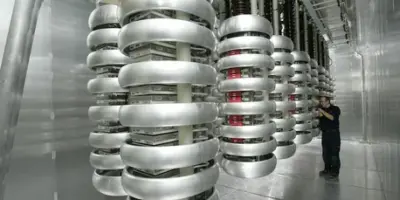

• Semiconductor Processing Furnace

• PVD&CVD Equipment

• Etching Equipment

• Others

Regional Analysis of Global Semiconductor Mass Flow Controller Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Semiconductor Mass Flow Controller market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Semiconductor Mass Flow Controller Market Research Report @ https://stringentdatalytics.com/purchase/semiconductor-mass-flow-controller-market/9810/

High Demand Drivers

- Semiconductor Industry Expansion:

- Advanced Manufacturing Processes: The adoption of advanced manufacturing techniques such as Extreme Ultraviolet (EUV) lithography, 3D NAND, and FinFET technology necessitates high-precision MFCs.

- Increased Chip Production: Growing demand for semiconductors in consumer electronics, automotive, and industrial applications drives the need for reliable MFCs to support high-volume chip production.

- Consumer Electronics Proliferation:

- Smart Devices: The surge in smartphones, tablets, and wearable devices requires advanced semiconductor components, leading to higher demand for MFCs in their fabrication.

- IoT Expansion: Increasing integration of IoT devices across various sectors amplifies the demand for semiconductors, consequently boosting the MFC market.

- Automotive and AI Applications:

- Automotive Electronics: The rise of electric vehicles (EVs), autonomous driving technologies, and advanced driver-assistance systems (ADAS) contributes to the demand for high-precision semiconductor components, spurring the need for MFCs.

- Artificial Intelligence: Growth in AI applications, including data centers and edge computing, requires advanced semiconductors, increasing the demand for MFCs in the manufacturing process.

- Emerging Technologies and Applications:

- Quantum Computing: Development of quantum computing technology relies on high-precision control of gases in semiconductor fabrication, boosting the demand for advanced MFCs.

- Photonics: Growth in photonics and optoelectronics requires precise gas flow control, expanding the market for MFCs.

Scope of the Market

- Application Areas:

- Chemical Vapor Deposition (CVD): MFCs regulate precursor gases in CVD processes, essential for depositing thin films on semiconductor wafers.

- Etching: Used to control the flow of etchants in etching processes, critical for defining intricate patterns on semiconductor wafers.

- Atomic Layer Deposition (ALD): MFCs ensure precise flow control in ALD processes, crucial for creating ultra-thin layers on semiconductor devices.

- Doping: Control dopant gas flow in doping processes, vital for modifying electrical properties of semiconductors.

- Regional Analysis:

- Asia-Pacific: Dominates the market due to the concentration of semiconductor manufacturing facilities in countries like China, Taiwan, and South Korea.

- North America: Significant growth driven by advancements in semiconductor technologies and substantial R&D investments.

- Europe: Growth supported by increasing adoption of advanced semiconductor applications in automotive and industrial sectors.

- Technology Trends:

- IoT Integration: Integration of IoT technology in MFCs for real-time monitoring and control to enhance process efficiency and reliability.

- AI and Machine Learning: Application of AI and machine learning for optimizing flow control, predictive maintenance, and improving manufacturing yields.

- Sustainable Practices: Development of eco-friendly and energy-efficient MFCs to meet increasing environmental regulations and sustainability goals.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Leave a Reply