Overview:

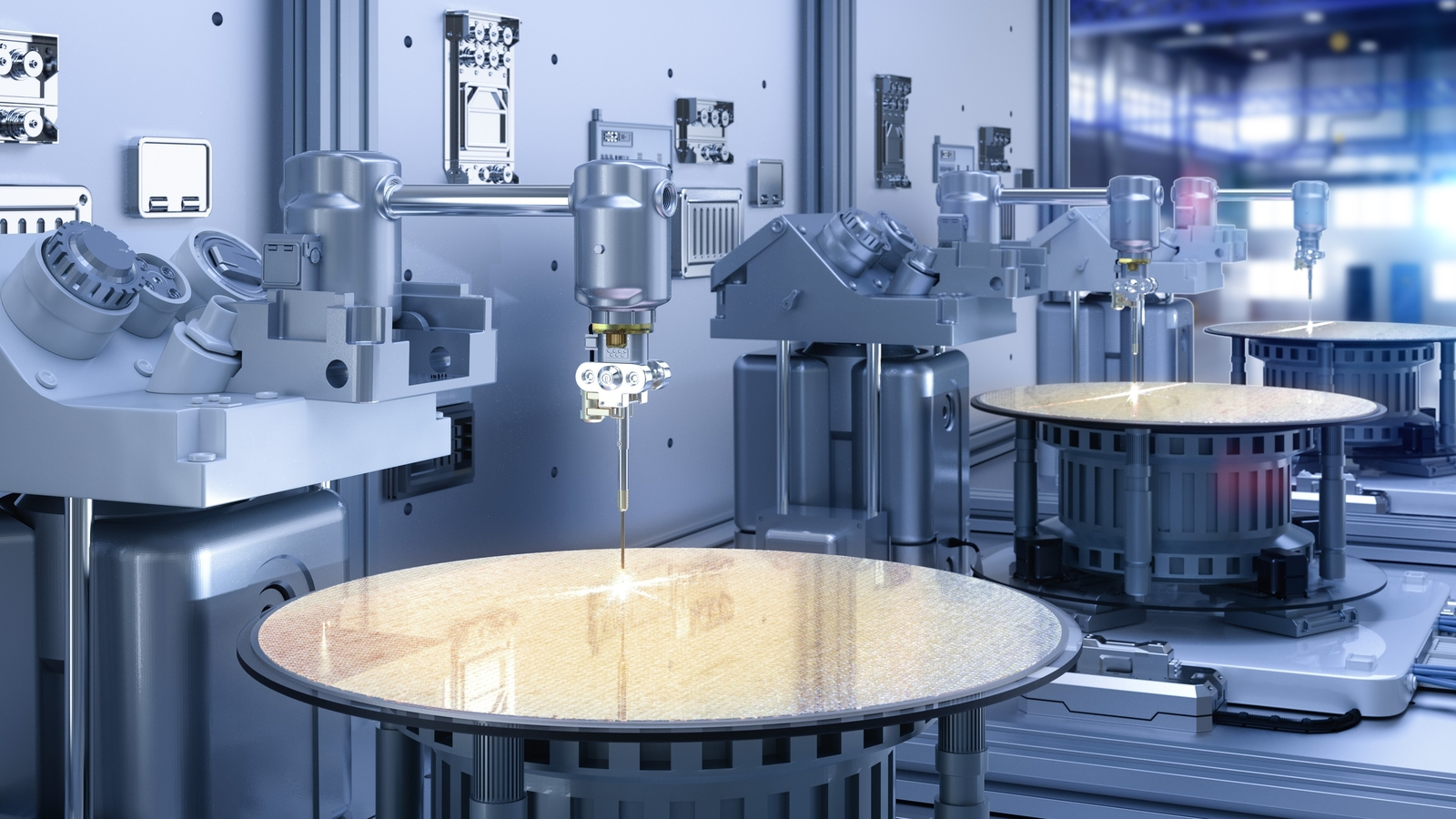

In the fast-paced world of precision manufacturing, technological advancements continue to reshape the landscape, offering unprecedented opportunities for efficiency and accuracy. One such innovation making waves is the Lithography Dual-Workpiece Table, a cutting-edge solution that has captivated industries reliant on high-precision manufacturing processes. This market is experiencing rapid growth, driven by the need for enhanced productivity, reduced production costs, and increased manufacturing flexibility.

Introduction to Lithography Dual-Workpiece Table:

Lithography, a cornerstone of semiconductor manufacturing, has traditionally relied on single-workpiece tables for the production of intricate microelectronic components. However, the limitations of this approach, including extended production times and higher costs, prompted the development of dual-workpiece tables. These tables enable simultaneous processing of two workpieces, leading to a paradigm shift in lithography technology.

Market Dynamics:

- Increasing Demand for High-Throughput Manufacturing: The Lithography Dual-Workpiece Table Market is witnessing a surge in demand, fueled by the ever-growing need for high-throughput manufacturing. With the capability to process two workpieces concurrently, these tables significantly enhance production speed, thereby meeting the escalating demand for microelectronic components in various industries.

- Cost-Efficiency and Resource Optimization: Traditional lithography setups often involve prolonged production cycles and increased operational costs. The dual-workpiece tables address these challenges by optimizing resources and streamlining the manufacturing process. Manufacturers are increasingly adopting this technology to achieve cost-efficiency without compromising on the quality and precision of their products.

- Enhanced Flexibility in Manufacturing: The Lithography Dual-Workpiece Table provides manufacturers with increased flexibility in production planning. The ability to handle different workpieces simultaneously allows for improved scheduling and quicker adaptation to changing production requirements. This flexibility is proving to be a crucial factor in industries with dynamic market demands.

- Advancements in Lithography Techniques: The market is benefitting from continuous advancements in lithography techniques, with dual-workpiece tables at the forefront of innovation. These tables are compatible with various lithography methods, including optical lithography and extreme ultraviolet (EUV) lithography, ensuring adaptability to evolving industry standards.

Receive the FREE Sample Report of Lithography Dual-workpiece Table Market Research Insights @ https://stringentdatalytics.com/sample-request/lithography-dual-workpiece-table-market/9053/

Market Segmentations:

Global Lithography Dual-workpiece Table Market: By Company

• ASML

• Beijing U-Precision Tech

• Nikon

Global Lithography Dual-workpiece Table Market: By Type

• 1.8nm

• 2nm

• Others

Global Lithography Dual-workpiece Table Market: By Application

• EUV Lithography

• DUV Lithography

Regional Analysis of Global Lithography Dual-workpiece Table Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Lithography Dual-workpiece Table market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Lithography Dual-workpiece Table Market Research Report @ https://stringentdatalytics.com/purchase/lithography-dual-workpiece-table-market/9053/

Here are key reasons why companies are opting to invest in Lithography Dual-Workpiece Tables:

- Increased Throughput and Production Speed: One of the primary reasons for purchasing Lithography Dual-Workpiece Tables is the substantial increase in throughput and production speed. These tables enable simultaneous processing of two workpieces, effectively reducing cycle times. Manufacturers can produce more microelectronic components in a given timeframe, meeting the growing demand for high-precision products.

- Cost-Efficiency and Resource Optimization: Dual-workpiece tables contribute to cost-efficiency by optimizing resources. The ability to process two workpieces concurrently minimizes operational costs associated with extended production times. This results in a more streamlined manufacturing process, reducing overall expenses and enhancing the competitiveness of businesses in the market.

- Flexibility in Production Planning: The flexibility offered by Lithography Dual-Workpiece Tables is a compelling reason for their adoption. Manufacturers can adapt quickly to changing production requirements and schedules. The ability to handle different workpieces simultaneously allows for improved planning and responsiveness to dynamic market demands, providing a competitive edge.

- Compatibility with Advanced Lithography Techniques: The market’s ongoing shift towards advanced lithography techniques, such as extreme ultraviolet (EUV) lithography, is seamlessly supported by dual-workpiece tables. Manufacturers can stay at the forefront of technology and industry standards, ensuring that their lithography processes remain cutting-edge and capable of handling evolving requirements.

- Enhanced Precision and Accuracy: Dual-workpiece tables are designed to uphold the highest standards of precision and accuracy. The simultaneous processing of workpieces minimizes variations between components, leading to consistent and high-quality outputs. This is particularly crucial in industries where the reliability and performance of microelectronic components are paramount.

- Competitive Edge and Market Differentiation: Companies investing in Lithography Dual-Workpiece Tables gain a competitive edge and can differentiate themselves in the market. The ability to offer faster turnaround times, cost-effective solutions, and adaptability to diverse manufacturing needs positions these businesses as leaders in the high-precision manufacturing landscape.

- Technological Advancements and Innovation: Leading players in the market, such as ASML, Canon, and Nikon, continuously invest in research and development to enhance the capabilities of dual-workpiece tables. Purchasing these advanced systems ensures access to the latest technological innovations, future-proofing manufacturing processes and maintaining a competitive advantage.

- Meeting Industry and Regulatory Standards: The Lithography Dual-Workpiece Tables comply with industry and regulatory standards, ensuring that manufacturers adhere to quality and safety requirements. Investing in these tables reflects a commitment to meeting the highest standards in precision manufacturing, instilling confidence in customers and stakeholders.

Challenges and Future Outlook:

While the Lithography Dual-Workpiece Table Market is experiencing remarkable growth, challenges such as initial implementation costs and the need for skilled personnel to operate these advanced systems are notable. However, ongoing research and development efforts are expected to address these challenges, making dual-workpiece tables more accessible to a broader range of manufacturers.

The future outlook for the market remains highly optimistic, with the technology poised to become a standard in precision manufacturing. As industries continue to demand faster production, lower costs, and increased flexibility, the Lithography Dual-Workpiece Table Market is set to play a pivotal role in shaping the future of high-precision manufacturing processes. With continuous innovation and strategic collaborations, the market is on track to redefine the possibilities of lithography technology, ushering in a new era of efficiency and excellence in manufacturing.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels: