The global Industrial Robot Sensors market was valued at USD 3,729.11 million in 2023 and is projected to reach USD 6,369.86 million by 2033, at a CAGR of 5.5% during the forecast period 2024-2033

Overview:

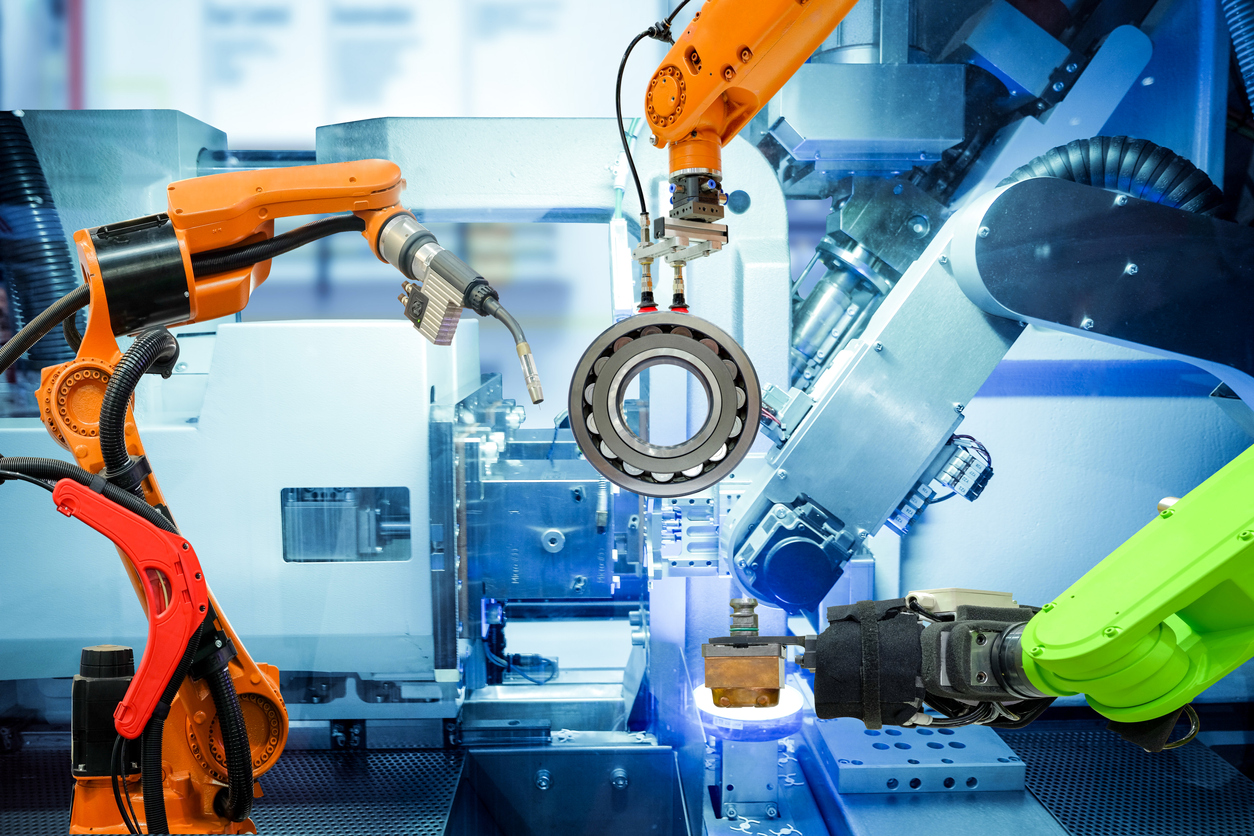

In the era of smart manufacturing, Industrial Robot Sensors stand at the forefront of innovation, reshaping the landscape of industrial automation. This comprehensive overview explores the evolution, key functionalities, market trends, challenges, and the promising future of Industrial Robot Sensors.

Evolution of Industrial Robot Sensors:

Industrial Robot Sensors have evolved from simple proximity detectors to sophisticated, intelligent devices that enable robots to perceive and interact with their environment. Initially designed for safety and collision avoidance, these sensors now play a pivotal role in enhancing the flexibility, efficiency, and precision of industrial robotic applications.

Key Functionalities:

- Collision Avoidance: Industrial Robot Sensors provide real-time feedback to robots, preventing collisions with obstacles or humans in their workspace. This ensures a safer working environment and protects both machinery and personnel.

- Precision and Accuracy: Sensors enable robots to precisely navigate their surroundings, improving accuracy in tasks such as pick-and-place operations, welding, and assembly. This is particularly crucial in industries where precision is paramount.

- Force and Torque Sensing: Advanced sensors allow robots to sense and adjust their force and torque during interactions with objects. This capability is essential in delicate tasks like handling fragile materials or performing intricate assembly operations.

- Vision Systems: Incorporating vision sensors, robots gain the ability to visually perceive and interpret their environment. This enhances their capabilities in tasks that require object recognition, quality inspection, and even collaborative applications.

Market Trends in Industrial Robot Sensors:

- Integration with Industry 4.0: As industries embrace the tenets of Industry 4.0, Industrial Robot Sensors are becoming integral components of interconnected and data-driven manufacturing systems. This integration enhances overall efficiency and enables predictive maintenance.

- Collaborative Robotics: The rise of collaborative robots, or cobots, is driving the demand for sensors that ensure safe human-robot collaboration. Sensors play a crucial role in detecting human presence and adjusting robot behavior accordingly.

- IoT Connectivity: Industrial Robot Sensors are increasingly equipped with IoT capabilities, allowing them to communicate seamlessly with other devices and systems. This connectivity facilitates real-time monitoring, data analysis, and remote control.

- Advancements in Artificial Intelligence: Integration of Artificial Intelligence (AI) in sensors enables robots to make more informed decisions based on real-time data. This enhances adaptive learning, enabling robots to optimize their performance over time.

Receive the FREE Sample Report of Industrial Robot Sensors Market Research Insights @ https://stringentdatalytics.com/sample-request/industrial-robot-sensors-market/12923/

Market Segmentations:

Global Industrial Robot Sensors Market: By Company

• ATI Industrial Automation

• Fanuc

• FUTEK Advanced Sensor Technology

• Honeywell International

• ams AG

• Cognex

• OTC Daihen

• Hermary Opto Electronics

• Inilabs

• MaxBotix

• Perception Robotics

• Roboception

• EPSON

• Tekscan

• Omron

• TE Connectivity (TE)

• Basler

• ISRA VISION

• NXP Semiconductors

• Freescale Semiconductor

• STMicroelectronics NV

• Texas Instruments

Global Industrial Robot Sensors Market: By Type

• Vision Sensors

• Force Torque Sensors

• Temperature Sensors

• Pressure Sensors

• Position Sensors

• Others

Global Industrial Robot Sensors Market: By Application

• Agriculture

• Automotive

• Healthcare

• Military

• Others

Regional Analysis of Global Industrial Robot Sensors Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Industrial Robot Sensors market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Industrial Robot Sensors Market Research Report @ https://stringentdatalytics.com/purchase/industrial-robot-sensors-market/12923/

Challenges and Opportunities:

- Cost Considerations: The initial cost of deploying advanced Industrial Robot Sensors can be a barrier for some industries. However, the long-term benefits, including increased efficiency and reduced downtime, often outweigh the initial investment.

- Complexity of Integration: Integrating sensors into existing robotic systems can be complex. This challenge presents opportunities for companies specializing in seamless integration solutions and fostering collaboration between sensor manufacturers and robotic system providers.

- Data Security Concerns: With increased connectivity, there is a growing concern about the security of data generated by sensors. Addressing cybersecurity issues is crucial to protect sensitive information and ensure the reliability of robotic systems.

Future Outlook:

The Industrial Robot Sensors market is poised for substantial growth as industries continue to prioritize automation, efficiency, and safety. The ongoing convergence of sensor technologies with AI, IoT connectivity, and Industry 4.0 principles will further propel the evolution of robotic systems, making them more adaptive, intelligent, and responsive to dynamic manufacturing environments.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Leave a Reply