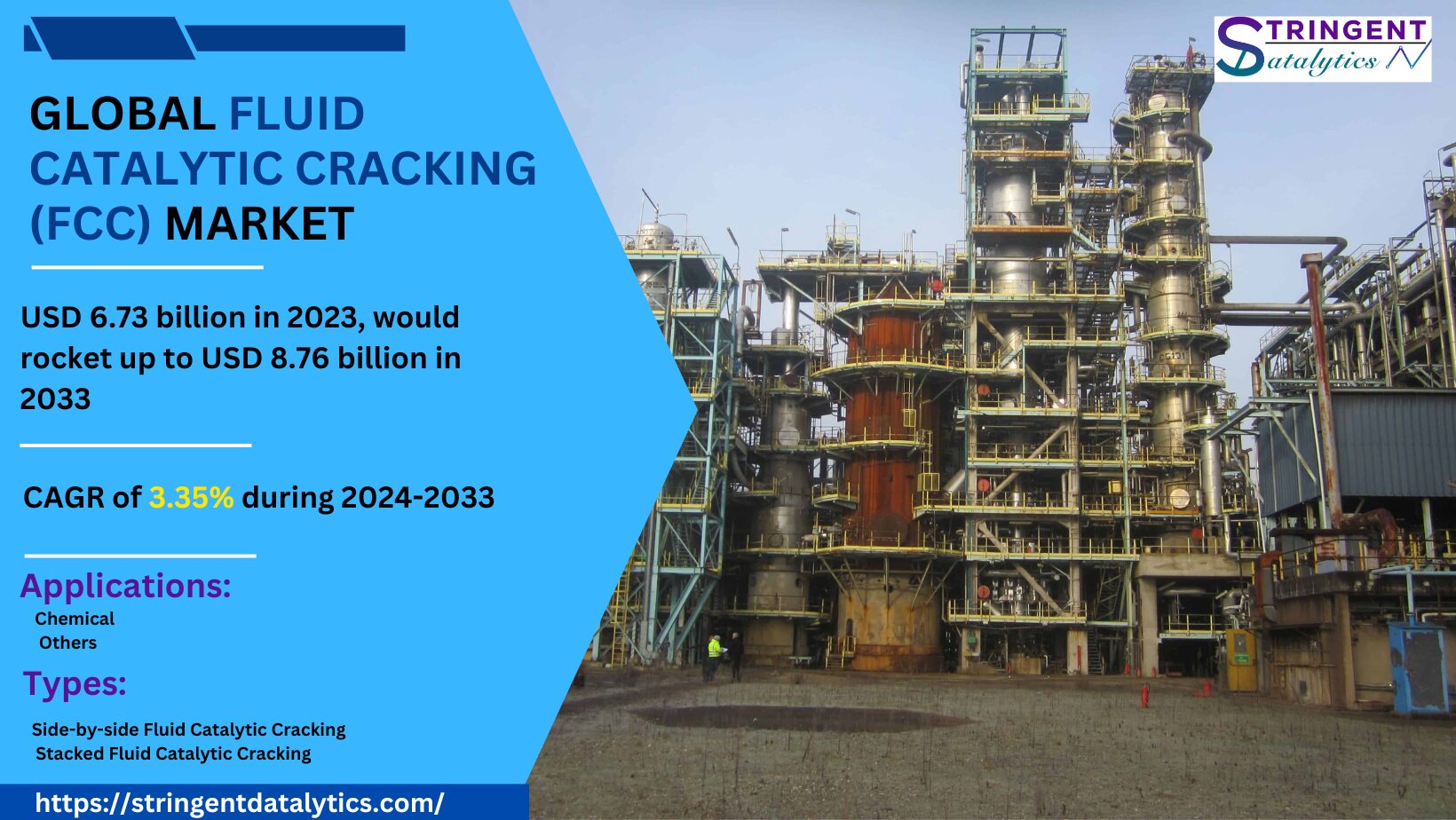

Fluid Catalytic Cracking (FCC) Market was USD 6.73 billion in 2023, would rocket up to USD 8.76 billion in 2033, and is expected to undergo a CAGR of 3.35% during 2024-2033.

Introduction

Fluid Catalytic Cracking (FCC) is a crucial process in petroleum refining, transforming heavy hydrocarbons into lighter, more valuable products such as gasoline, diesel, and olefins. This process significantly enhances the yield and quality of fuels, making it indispensable in modern refineries. The FCC market encompasses the equipment, catalysts, and services essential for FCC operations.

Market Analysis

The FCC market is segmented based on component type (equipment, catalysts), application (gasoline production, olefin production, others), and geography. Key players in the market include Albemarle Corporation, BASF SE, ExxonMobil Corporation, and Honeywell UOP.

Market Drivers:

- Rising Demand for High-Octane Fuels: The increasing global demand for gasoline and other high-octane fuels drives the growth of the FCC market.

- Stringent Environmental Regulations: Regulations aimed at reducing emissions and improving fuel quality boost the adoption of advanced FCC technologies.

- Technological Advancements: Innovations in FCC catalysts and process optimization enhance efficiency and product yield.

- Growing Refining Capacity: Expansion of refining capacities, especially in emerging economies, fuels the demand for FCC units.

Challenges:

- High Capital and Operational Costs: The initial setup and ongoing maintenance of FCC units involve substantial investment.

- Feedstock Quality Variability: Variability in crude oil quality can impact the efficiency and output of FCC processes.

- Environmental Concerns: Managing the environmental impact of FCC operations, including catalyst disposal and emissions, presents ongoing challenges.

Key Trends and Factors

- Advancements in Catalyst Technology: Development of more efficient and environmentally friendly catalysts that enhance conversion rates and selectivity.

- Integration with Petrochemical Production: Increasing integration of FCC units with petrochemical production to maximize output of valuable chemicals like propylene and butylene.

- Digitalization and Automation: Adoption of digital technologies and automation for real-time monitoring and optimization of FCC operations.

- Sustainability Initiatives: Efforts to reduce the environmental footprint of FCC operations through improved catalyst recycling, energy efficiency, and emission control technologies.

Working and Technology

FCC Operation:

- Feedstock Preheating: Heavy hydrocarbon feedstock is preheated before entering the FCC unit.

- Cracking Reaction: The preheated feedstock is mixed with a hot catalyst in the reactor, causing the large hydrocarbon molecules to crack into smaller, more valuable molecules.

- Catalyst Regeneration: The catalyst, now coated with coke, is separated from the cracked products and sent to a regenerator where the coke is burned off, restoring the catalyst’s activity.

- Product Separation: The cracked hydrocarbon products are separated in a fractionator into different streams such as gasoline, diesel, and gases.

Key Technologies:

- Zeolite Catalysts: Zeolites are widely used in FCC due to their high activity and selectivity in cracking reactions.

- Advanced Reactor Designs: Innovations in reactor design enhance contact between feedstock and catalyst, improving conversion rates.

- Emission Control Systems: Technologies to capture and reduce emissions from FCC units, including sulfur oxides and nitrogen oxides.

Receive the FREE Sample Report of Fluid Catalytic Cracking (FCC) Market Research Insights @ https://stringentdatalytics.com/sample-request/fluid-catalytic-cracking-(fcc)-market/14962/

Market Segmentations:

Global Fluid Catalytic Cracking (FCC) Market: By Company

Albemarle Corporation

WR Grace Company

BASF SE

Flour Corporation

Shell Global solutions

UOP

Chevron Lummus Global

McDermott

Axens

Exxonmobil

Global Fluid Catalytic Cracking (FCC) Market: By Type

Side-by-side Fluid Catalytic Cracking

Stacked Fluid Catalytic Cracking

Global Fluid Catalytic Cracking (FCC) Market: By Application

Chemical

Others

Regional Analysis of Global Fluid Catalytic Cracking (FCC) Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Fluid Catalytic Cracking (FCC) market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Fluid Catalytic Cracking (FCC) Market Research Report @ https://stringentdatalytics.com/purchase/fluid-catalytic-cracking-(fcc)-market/14962/?license=single

Historical Developments

Early Developments:

- FCC technology was developed in the 1940s to address the growing demand for high-octane gasoline during World War II.

Significant Milestones:

- 1950s-1970s: Adoption of zeolite catalysts significantly improved the efficiency and output of FCC units.

- 1980s-1990s: Development of advanced reactor and regenerator designs enhanced process performance.

- 2000s-Present: Integration with petrochemical production and advancements in catalyst technology continue to drive market growth.

Objective

The primary objective of FCC technology is to maximize the production of valuable lighter hydrocarbons from heavier crude oil fractions. This involves improving the yield and quality of products like gasoline and propylene while ensuring cost-effectiveness and compliance with environmental regulations.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Leave a Reply