Wafer Carriers for MOCVD Market Overview

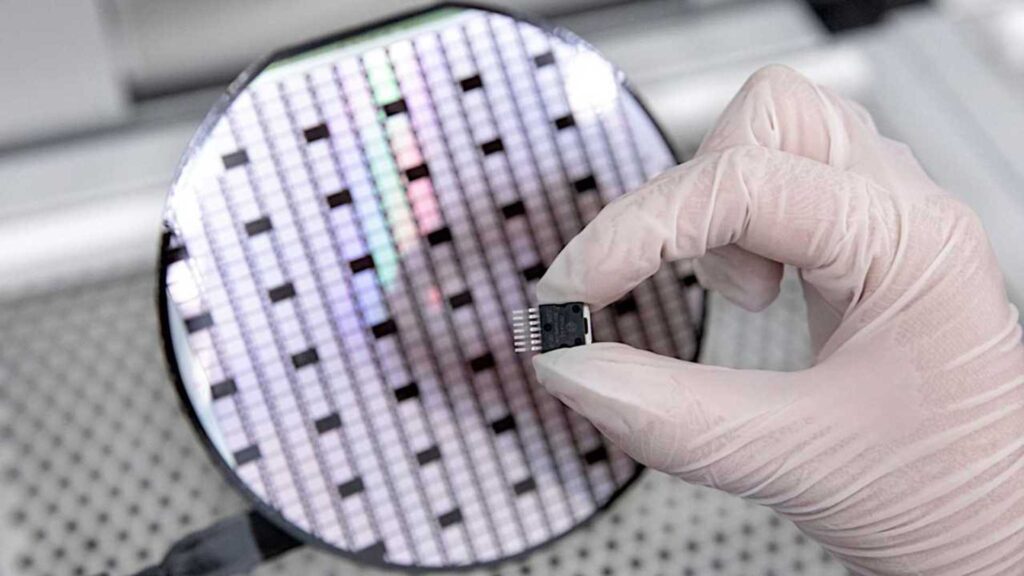

The market for Wafer Carriers in Metal Organic Chemical Vapor Deposition (MOCVD) processes plays a critical role in enabling the production of advanced semiconductor devices. MOCVD is a key process in the fabrication of compound semiconductor materials, including gallium nitride (GaN), gallium arsenide (GaAs), and indium phosphide (InP), which are essential for various applications such as LEDs, power electronics, and wireless communication devices. Wafer carriers serve as a crucial component in MOCVD systems, facilitating the transportation and handling of semiconductor wafers throughout the deposition process.

Industry Description and Outlook

The MOCVD market has witnessed significant growth in recent years, driven by the increasing demand for high-performance semiconductor devices across various industries. The proliferation of technologies such as 5G networks, Internet of Things (IoT) devices, and electric vehicles (EVs) has fueled the demand for compound semiconductors, thereby driving the adoption of MOCVD systems and related components like wafer carriers.

The market for wafer carriers in MOCVD applications is characterized by intense competition and rapid technological advancements. Manufacturers in this industry continuously strive to develop innovative solutions that improve wafer handling efficiency, maximize yield, and ensure the highest quality of deposited films. Moreover, the increasing focus on automation and process optimization is driving the demand for advanced wafer carrier designs that offer enhanced reliability and performance.

Target Market and Trends

The primary target market for wafer carriers in MOCVD applications includes semiconductor manufacturers, research institutions, and foundries involved in the production of compound semiconductor devices. With the growing adoption of MOCVD technology across various end-use industries, the demand for wafer carriers is expected to witness a steady increase in the coming years.

Key trends shaping the wafer carrier market in the MOCVD industry include:

- Miniaturization and High-Throughput: As semiconductor devices become smaller and more complex, there is a growing demand for wafer carriers capable of handling smaller wafer sizes and increasing throughput. Manufacturers are developing compact and high-density wafer carrier designs to accommodate more wafers per deposition run, thereby improving overall production efficiency.

- Material Innovation: The choice of materials for wafer carriers is crucial in ensuring compatibility with MOCVD processes and maintaining the integrity of deposited films. There is a trend towards the adoption of advanced materials such as quartz, silicon carbide (SiC), and specialized coatings that offer superior chemical resistance, thermal stability, and minimal contamination.

- Customization and Flexibility: Semiconductor manufacturers require wafer carriers that can accommodate diverse wafer sizes, configurations, and materials to support a wide range of production requirements. Customization capabilities, including adjustable slot configurations and modular designs, are becoming increasingly important to meet the specific needs of different applications and customer preferences.

- Integration of Smart Technologies: The integration of smart sensors and monitoring systems within wafer carriers is emerging as a key trend in the MOCVD industry. Real-time monitoring of wafer temperature, pressure, and deposition parameters enables proactive maintenance, process optimization, and quality control, leading to higher yields and reduced downtime.

Key Success Factors

Several factors contribute to success in the wafer carrier market for MOCVD applications:

- Technical Expertise and Innovation: Companies need to continuously invest in research and development to stay at the forefront of technological advancements in wafer carrier design and manufacturing. Innovation in materials, manufacturing processes, and automation technologies is essential to meet the evolving needs of semiconductor manufacturers.

- Quality and Reliability: Wafer carriers play a critical role in ensuring the quality and uniformity of deposited films in MOCVD processes. Manufacturers must adhere to strict quality standards and rigorous testing protocols to deliver reliable and durable wafer carrier solutions that meet the demanding requirements of semiconductor fabrication.

- Customer Collaboration and Support: Building strong relationships with customers and understanding their unique requirements is vital for success in the wafer carrier market. Collaborating closely with semiconductor manufacturers to provide tailored solutions, technical support, and after-sales services fosters long-term partnerships and enhances customer satisfaction.

- Operational Efficiency and Supply Chain Management: Efficient manufacturing processes, streamlined logistics, and effective supply chain management are essential for meeting customer demand, minimizing lead times, and optimizing costs. Companies need to invest in lean manufacturing practices, inventory management systems, and strategic partnerships to ensure operational excellence.

Receive the FREE Sample Report of Wafer Carriers for MOCVD Market Research Insights @ https://stringentdatalytics.com/sample-request/wafer-carriers-for-mocvd-market/7940/

Market Segmentations:

Global Wafer Carriers for MOCVD Market: By Company

• Toyo Tanso

• SGL Carbon

• Tokai Carbon

• Mersen

• Bay Carbon

• CoorsTek

• Schunk Xycarb Technology

• ZhiCheng Semiconductor

Global Wafer Carriers for MOCVD Market: By Type

• GaN

• InP

• Other

Global Wafer Carriers for MOCVD Market: By Application

• LED Lighting

• Advanced Packaging and MEMS

• Semiconductors

• Others

Regional Analysis of Global Wafer Carriers for MOCVD Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Wafer Carriers for MOCVD market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Wafer Carriers for MOCVD Market Research Report @ https://stringentdatalytics.com/purchase/wafer-carriers-for-mocvd-market/7940/

Projections

The future outlook for the wafer carrier market in MOCVD applications remains positive, driven by continued advancements in semiconductor technology and increasing demand for compound semiconductor devices. Key projections for the market include:

- Market Growth: The market for wafer carriers in MOCVD applications is expected to grow at a steady pace, supported by the expansion of industries such as automotive, consumer electronics, and telecommunications that rely on compound semiconductor technologies.

- Technology Advancements: Ongoing research and development efforts will lead to the introduction of advanced wafer carrier designs with enhanced performance, reliability, and functionality. Innovations in materials, sensors, and automation technologies will drive further improvements in wafer handling efficiency and process control.

- Industry Consolidation: The wafer carrier market is likely to witness increased consolidation as companies seek to strengthen their competitive positions through mergers, acquisitions, and strategic partnerships. This consolidation trend is expected to result in larger, more diversified players with broader product portfolios and global reach.

- Emerging Applications: The adoption of MOCVD technology is expanding beyond traditional applications such as LEDs and power electronics to new areas such as quantum computing, photonics, and advanced sensors. This diversification of applications will create opportunities for wafer carrier manufacturers to address niche markets and niche applications with specialized solutions.

Environmental Factors

Environmental sustainability is an increasingly important consideration in the semiconductor industry, including the production of wafer carriers for MOCVD applications. Manufacturers are under pressure to minimize energy consumption, reduce waste generation, and adopt eco-friendly materials and processes.

Key environmental factors shaping the wafer carrier market include:

- Material Selection: Choosing environmentally friendly materials with minimal environmental impact is essential for sustainable wafer carrier manufacturing. Companies are exploring alternatives to traditional materials that are energy-intensive or generate hazardous waste during production and disposal.

- Energy Efficiency: Improving energy efficiency in wafer carrier manufacturing processes helps reduce carbon emissions and operating costs. Adopting energy-efficient equipment, optimizing process parameters, and implementing renewable energy sources contribute to a greener manufacturing footprint.

- Recycling and Waste Management: Implementing recycling programs for wafer carriers at the end of their lifecycle helps minimize waste and conserve resources. Designing wafer carriers for disassembly and using recyclable materials facilitate the recovery and reuse of valuable components, reducing the environmental impact of disposal.

- Regulatory Compliance: Compliance with environmental regulations and standards governing hazardous substances, emissions, and waste disposal is critical for wafer carrier manufacturers. Adhering to industry best practices and obtaining relevant certifications demonstrates a commitment to environmental responsibility and sustainable business practices.

In conclusion, the market for wafer carriers in MOCVD applications is poised for growth, driven by technological advancements, increasing demand for compound semiconductor devices, and a focus on operational efficiency and sustainability. Companies that prioritize innovation, quality, customer collaboration, and environmental stewardship are well-positioned to succeed in this dynamic and competitive industry.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels: