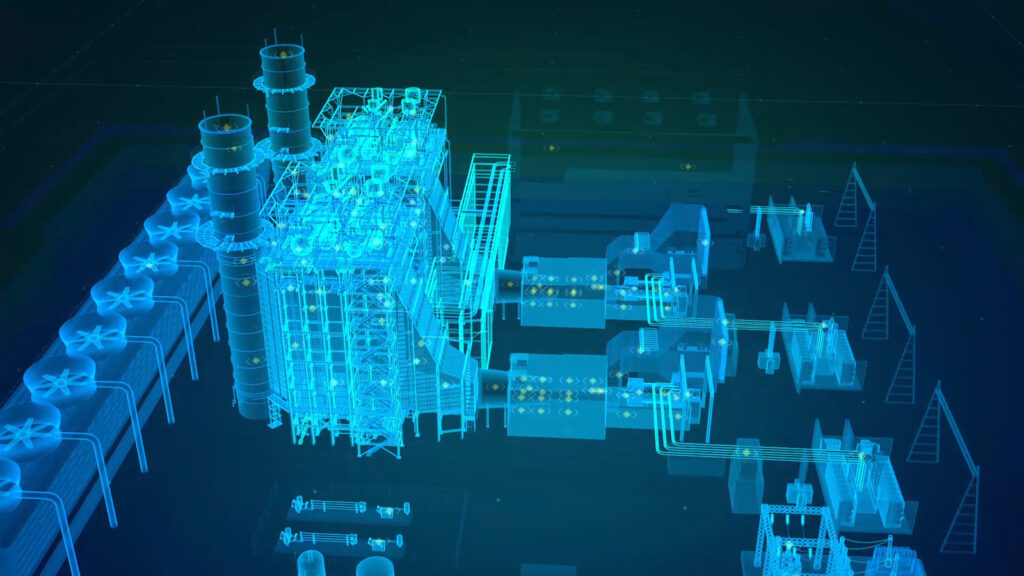

The Virtual Factory System Market is witnessing rapid growth as manufacturing companies adopt digital twin technologies to optimize production processes, improve efficiency, and reduce costs. Virtual factory systems create digital replicas of physical manufacturing facilities, enabling real-time monitoring, simulation, and optimization of production activities. These systems leverage technologies such as IoT, AI, machine learning, and simulation software to create virtual representations of factory assets, workflows, and operations.

Market Trends

- Digital Twin Technology Adoption: Virtual factory systems leverage digital twin technology to create accurate and dynamic models of manufacturing processes, equipment, and resources. Digital twins enable real-time monitoring, analysis, and optimization of factory operations, leading to improved efficiency and productivity.

- IoT-Enabled Sensor Networks: Virtual factory systems integrate IoT-enabled sensor networks to collect real-time data from manufacturing equipment, machinery, and production lines. Sensors monitor key performance indicators (KPIs) such as equipment utilization, energy consumption, and production quality, enabling proactive maintenance and optimization.

- Simulation and Modeling Tools: Simulation and modeling tools play a crucial role in virtual factory systems, enabling manufacturers to simulate production scenarios, test process changes, and optimize workflows before implementation. Simulation software helps identify potential bottlenecks, improve resource allocation, and minimize production downtime.

Market Drivers

- Industry 4.0 Adoption: The adoption of Industry 4.0 principles, such as automation, connectivity, and data-driven decision-making, is driving demand for virtual factory systems. Manufacturers are leveraging digital technologies to create smart, interconnected production environments that optimize efficiency and flexibility.

- Demand for Operational Efficiency: Manufacturers are under pressure to improve operational efficiency, reduce costs, and increase competitiveness in the global market. Virtual factory systems enable manufacturers to optimize production processes, minimize waste, and maximize resource utilization, resulting in cost savings and improved profitability.

- Complexity of Manufacturing Operations: Modern manufacturing operations are becoming increasingly complex, with diverse product portfolios, customization requirements, and global supply chains. Virtual factory systems help manufacturers manage this complexity by providing visibility, control, and optimization across all aspects of production.

Get Free Exclusive PDF Sample Copy of This Research Report https://stringentdatalytics.com/sample-request/virtual-factory-system-market/5768/

Market Segmentations:

Global Virtual Factory System Market: By Company

- Siemens

- SAP

- Schneider Electric

- CCAU

- Bufab Group Box

- TMEIC

- Rockwell Automation, Inc.

- G2DT

- VF-KDO

- NVIDIA

Global Virtual Factory System Market: By Type

- Cloud-Based

- Local Deployment

Global Virtual Factory System Market: By Application

- Aerospace

- Chemical Industry

- Automobile Industry

- Food Industry

- Medical Industry

Click Here, To Buy Premium Report Market Outlook: https://stringentdatalytics.com/purchase/virtual-factory-system-market/5768/?license=single

Key Questions Answered in this Report:

- What is a Virtual Factory System, and how does it simulate manufacturing processes?

- How do Virtual Factory Systems contribute to Industry 4.0 initiatives and digital transformation in manufacturing?

- What are the key components and features of a Virtual Factory System?

- How do Virtual Factory Systems improve production planning and optimization?

- What role does digital twinning play in Virtual Factory Systems?

- How do Virtual Factory Systems integrate with other manufacturing technologies, such as IoT and automation?

- What are the benefits of using Virtual Factory Systems for manufacturers?

- How do Virtual Factory Systems support supply chain management and logistics?

- What are the challenges faced by manufacturers when implementing Virtual Factory Systems?

Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Virtual Factory System market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Reasons to Purchase this Report:

- To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

- To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

- To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

- To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

- To make informed business decisions: this research reports provide businesses with data-driven insights that can help them make informed business decisions, including strategic planning, product development, and marketing and advertising strategies.

About Stringent Datalytics:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Contact Us

Stringent Datalytics

Contact No- +1 346 666 6655

Email Id- sales@stringentdatalytics.com

Web- https://stringentdatalytics.com/