The vacuum wafer chucks market experienced notable growth from 2023 to the projected value for 2033, increasing from USD 197.47 million to USD 339.71 million. This indicates a significant expansion (CAGR) at 5.6% during the forecast period 2024-2033

1. Introduction

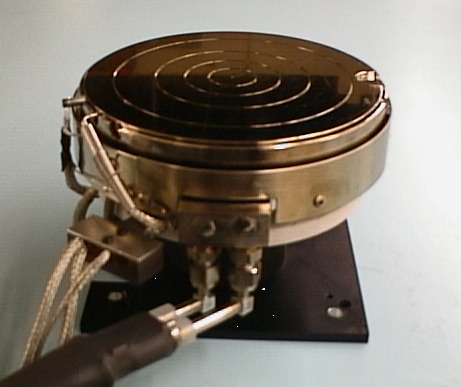

The vacuum wafer chucks market is a crucial segment within the semiconductor and electronics manufacturing industry. Vacuum wafer chucks are used to securely hold wafers during various processes such as lithography, etching, and inspection. These chucks utilize vacuum technology to ensure the precise positioning and stability of wafers, which is essential for achieving high yields and quality in semiconductor fabrication. The market is witnessing growth due to the increasing demand for advanced semiconductor devices and the expansion of applications in various high-tech industries, including electronics, photovoltaics, and MEMS (Micro-Electro-Mechanical Systems).

2. Growth Drivers

2.1. Increasing Demand for High-Precision Semiconductor Devices

- Advanced Electronics: The growth in demand for smaller, faster, and more efficient electronic devices necessitates high-precision semiconductor manufacturing processes, driving the demand for advanced vacuum wafer chucks.

- Integrated Circuits (ICs): The complexity of modern ICs, which require exact alignment and handling during production, boosts the need for reliable vacuum wafer chucks.

2.2. Expansion of Semiconductor Applications

- Consumer Electronics: The proliferation of consumer electronics such as smartphones, tablets, and wearables requires efficient wafer handling solutions to meet production needs.

- Automotive Electronics: Increasing use of semiconductors in automotive applications, such as advanced driver-assistance systems (ADAS) and electric vehicles (EVs), contributes to market growth.

- 5G Technology: The rollout of 5G technology drives demand for high-frequency semiconductor devices, necessitating precise wafer handling.

2.3. Advances in Semiconductor Manufacturing

- Miniaturization Trends: As semiconductor devices continue to shrink in size, the need for precise wafer handling becomes critical, driving innovations in vacuum wafer chuck technology.

- Complex Fabrication Processes: The growing complexity of semiconductor fabrication processes requires advanced handling equipment to ensure accuracy and minimize defects.

2.4. Increasing Production Capacities

- Expansion of Foundries: The expansion of semiconductor foundries and increased production capacities to meet global demand for semiconductors fuels the market for vacuum wafer chucks.

- Investment in Semiconductor Infrastructure: Significant investments in semiconductor infrastructure globally are boosting the demand for high-performance wafer handling equipment.

3. Emerging Technologies

3.1. Advanced Vacuum Systems

- Enhanced Vacuum Control: Innovations in vacuum systems provide better control and stability, ensuring consistent wafer handling and reducing the risk of defects.

- Multi-Zone Vacuum Chucks: Development of multi-zone vacuum chucks allows for better control over wafer positioning, improving precision in semiconductor processing.

3.2. Adaptive Chucking Technologies

- Smart Chucks: Integration of sensors and real-time monitoring technologies in vacuum chucks enhances their functionality, enabling adaptive control based on wafer characteristics and process requirements.

- Adaptive Vacuum Gripping: Technologies that adjust the vacuum grip based on wafer size, thickness, and material composition improve handling versatility and reduce damage risks.

3.3. Integration with Automation Systems

- Automated Wafer Handling: Integration of vacuum wafer chucks with automated wafer handling systems increases efficiency and throughput in semiconductor fabrication lines.

- Robotic Interfaces: Advanced robotic interfaces with vacuum chucks allow for seamless wafer transfer between different processing stages, enhancing productivity and reducing manual intervention.

3.4. Material Innovations

- Advanced Materials: Development of new materials for vacuum wafer chucks, such as ceramics and composites, offers enhanced thermal stability, reduced contamination, and improved durability.

- Non-Contact Holding Techniques: Innovations in non-contact wafer holding techniques reduce particle contamination and mechanical stress, improving wafer quality and yield.

4. Strategic Opportunities

4.1. Market Expansion in Emerging Regions

- Asia-Pacific Dominance: Expansion in semiconductor manufacturing in the Asia-Pacific region presents significant opportunities for vacuum wafer chuck suppliers, driven by the presence of major semiconductor foundries and electronics manufacturers.

- Growing Demand in North America and Europe: Increasing investments in semiconductor infrastructure in North America and Europe create opportunities for market growth.

4.2. Product Differentiation and Customization

- Customized Solutions: Offering customized vacuum wafer chucks tailored to specific applications and customer requirements can differentiate products and capture niche markets.

- Enhanced Features: Developing chucks with enhanced features such as integrated metrology, advanced vacuum control, and material compatibility can attract high-end customers.

4.3. Partnerships and Collaborations

- Strategic Alliances: Forming partnerships with semiconductor equipment manufacturers and research institutions can foster innovation and expand market reach.

- Collaborative R&D: Collaborative research and development initiatives can lead to the creation of next-generation vacuum wafer chuck technologies and solutions.

4.4. Focus on Sustainability

- Eco-Friendly Designs: Developing vacuum wafer chucks with eco-friendly materials and energy-efficient designs aligns with the growing focus on sustainable semiconductor manufacturing practices.

- Recyclable Components: Innovations in recyclable and reusable components for vacuum wafer chucks can reduce environmental impact and appeal to environmentally conscious customers.

Receive the FREE Sample Report of Vacuum Wafer Chucks Market Research Insights @ https://stringentdatalytics.com/sample-request/vacuum-wafer-chucks-market/9701/

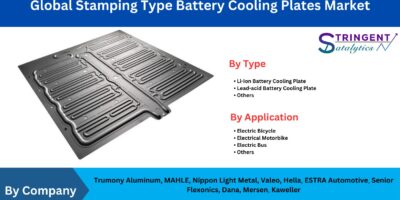

Market Segmentations:

Global Vacuum Wafer Chucks Market: By Company

• Disco

• NTK CERATEC CO., LTD.

• Tokyo Seimitsu

• Kyocera

• KINIK Company

• Cepheus Technology Ltd.

• Zhengzhou Research Institute for Abrasives & Grinding Co., Ltd.

• SemiXicon

• MACTECH

• RPS Co., Ltd.

Global Vacuum Wafer Chucks Market: By Type

• 300 mm Wafer

• 200 mm Wafer

• Others

Global Vacuum Wafer Chucks Market: By Application

• Wafer Suppliers

• Semiconductor Equipment Suppliers

Regional Analysis of Global Vacuum Wafer Chucks Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Vacuum Wafer Chucks market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Vacuum Wafer Chucks Market Research Report @ https://stringentdatalytics.com/purchase/vacuum-wafer-chucks-market/9701/

5. Innovations in Vacuum Wafer Chucks

5.1. Enhanced Vacuum Generation Techniques

- High-Efficiency Pumps: Development of high-efficiency vacuum pumps reduces energy consumption and improves the performance of vacuum wafer chucks.

- Vacuum Stability: Innovations in vacuum generation techniques enhance stability, ensuring consistent wafer handling throughout the manufacturing process.

5.2. Advanced Surface Coatings

- Anti-Contamination Coatings: Application of advanced surface coatings on vacuum chucks minimizes contamination and particle generation, improving wafer quality.

- Wear-Resistant Coatings: Development of wear-resistant coatings extends the lifespan of vacuum chucks, reducing maintenance costs and downtime.

5.3. Real-Time Monitoring Systems

- Integrated Sensors: Integration of sensors for real-time monitoring of vacuum levels, wafer position, and temperature enhances control and reduces the risk of handling errors.

- Data Analytics: Utilization of data analytics and machine learning algorithms to optimize vacuum chuck performance based on historical data and process parameters.

5.4. Modular Chuck Designs

- Interchangeable Components: Modular designs with interchangeable components allow for quick adjustments and repairs, reducing downtime and increasing flexibility.

- Scalable Solutions: Development of scalable vacuum chuck solutions that can be adapted to different wafer sizes and process requirements enhances versatility.

5.5. Ultra-Precision Chucking

- High-Precision Alignment: Innovations in high-precision alignment mechanisms improve the accuracy of wafer placement, crucial for advanced semiconductor fabrication processes.

- Thermal Management: Enhanced thermal management systems in vacuum chucks maintain stable wafer temperatures, reducing thermal distortions and improving process outcomes.

6. Demand and Supply Dynamics

6.1. Increasing Demand for Semiconductor Devices

- Consumer Electronics Boom: The surge in consumer electronics demand, including smartphones, laptops, and wearables, drives the need for advanced wafer handling solutions.

- Automotive Sector Growth: The rise of electric and autonomous vehicles increases the demand for semiconductor devices, fueling the vacuum wafer chuck market.

6.2. Supply Chain Considerations

- Raw Material Availability: The supply of high-quality materials for vacuum wafer chucks, such as advanced ceramics and composites, is crucial for maintaining production quality.

- Manufacturing Capabilities: Expanding manufacturing capabilities and capacities to meet growing demand is essential for vacuum wafer chuck suppliers.

6.3. Impact of Technological Advancements

- Innovative Solutions: Adoption of innovative vacuum wafer chuck solutions enhances production efficiency and quality, influencing market demand.

- Adoption of Automation: The integration of automation and robotics in semiconductor manufacturing increases the need for advanced wafer handling systems.

7. Future Forecast

7.1. Market Growth Projections

- Steady Growth: The global vacuum wafer chucks market is expected to experience steady growth over the next decade, driven by the increasing demand for semiconductor devices and advancements in wafer handling technology.

- CAGR Estimates: The market is projected to grow at a compound annual growth rate (CAGR) of 6-8% from 2024 to 2030, with significant contributions from the Asia-Pacific region and advancements in semiconductor manufacturing.

7.2. Technological Evolution

- Next-Generation Chucks: Development of next-generation vacuum wafer chucks with enhanced precision, adaptability, and integration capabilities will drive market growth.

- Focus on Integration: Increasing integration of vacuum chucks with automated and intelligent wafer handling systems will shape the future of semiconductor manufacturing.

7.3. Market Trends

- Customization Demand: Growing demand for customized vacuum wafer chucks tailored to specific semiconductor applications will influence product development and market strategies.

- Sustainability Focus: Emphasis on sustainable manufacturing practices will drive the adoption of eco-friendly and energy-efficient vacuum wafer chuck solutions.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

Leave a Reply