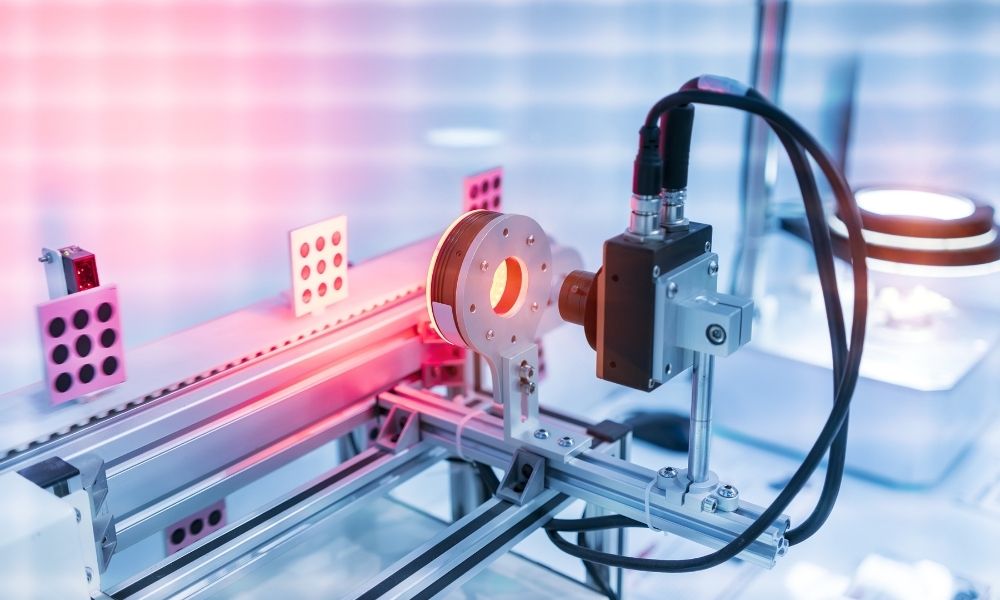

The global Industrial Laser Sensor Market was valued at USD 1,303.00 million in 2023, and it is expected to reach a value of USD 3,261.72 million by 2033 registering a CAGR of 9.61% during the forecast period (2024 – 2023).

Industrial Laser Sensor Market Overview:

- Market Size and Growth: The industrial laser sensor market has witnessed significant growth in recent years, driven by the increasing demand for precision measurement and sensing in industrial applications. The market size is expanding due to the rising adoption of automation and Industry 4.0 technologies across various sectors.

- Application Diversity: Industrial laser sensors find applications in a wide range of industries such as manufacturing, automotive, aerospace, healthcare, and more. Their versatility and capability to provide accurate and real-time data make them essential for tasks like distance measurement, object detection, and quality control.

- Advancements in Technology: Ongoing technological developments in laser sensor technology, including improvements in laser diode technology, signal processing, and miniaturization, are contributing to enhanced sensor performance. These advancements are leading to more reliable, compact, and cost-effective solutions, driving further market adoption.

- Integration with IoT and Industry 4.0: Industrial laser sensors are increasingly being integrated into Internet of Things (IoT) ecosystems and Industry 4.0 frameworks. This integration enables seamless communication between sensors, machines, and control systems, fostering a smarter and more interconnected industrial environment.

- Global Regulatory Standards and Compliance: The market is influenced by global regulatory standards governing safety and performance in industrial settings. Compliance with these standards is a crucial factor influencing the purchase of industrial laser sensors, ensuring that they meet necessary quality and safety requirements.

Key Factors Driving the Industrial Laser Sensor Market:

- Precision and Accuracy Requirements: Industries with high precision and accuracy requirements, such as semiconductor manufacturing and medical device production, are major drivers for the adoption of industrial laser sensors. These sensors provide the necessary accuracy for critical measurements.

- Cost-Effectiveness and Efficiency: As the cost of industrial laser sensors continues to decrease, industries are finding them more cost-effective compared to alternative sensing technologies. Additionally, the efficiency gained through automation and real-time data acquisition is a key factor driving adoption.

- Increasing Automation in Industries: The trend towards automation in manufacturing and industrial processes necessitates advanced sensors like industrial laser sensors. They play a crucial role in automating tasks such as object detection, positioning, and quality control, contributing to increased efficiency and reduced manual intervention.

- Rising Focus on Quality Control: Industries are placing a growing emphasis on quality control to ensure the production of high-quality goods. Industrial laser sensors, with their ability to provide precise measurements and detect defects, are becoming integral to quality control processes.

- Safety and Compliance Requirements: Stringent safety regulations in industries, especially in sectors like aerospace and automotive, are driving the adoption of industrial laser sensors for applications such as collision avoidance, ensuring compliance with safety standards.

Latest Technological Developments:

- Miniaturization and Compact Designs: Ongoing advancements focus on making industrial laser sensors more compact and lightweight, allowing for easier integration into various industrial systems and machinery.

- Multi-Sensor Integration: Manufacturers are developing solutions that combine industrial laser sensors with other types of sensors (e.g., vision sensors, proximity sensors) to provide a comprehensive sensing approach, enhancing overall system capabilities.

- Enhanced Range and Resolution: Continuous improvements in laser technology are extending the sensing range of industrial laser sensors while simultaneously enhancing their resolution. This enables these sensors to handle diverse applications with varying measurement requirements.

- Wireless Connectivity: The integration of wireless communication capabilities in industrial laser sensors facilitates seamless connectivity in IoT environments, enabling remote monitoring, data analysis, and control.

- Advanced Signal Processing Algorithms: The incorporation of advanced signal processing algorithms enhances the capabilities of industrial laser sensors in terms of filtering noise, improving accuracy, and enabling more sophisticated data analysis.

Receive the FREE Sample Report of Industrial Laser Sensor Market Research Insights @ https://stringentdatalytics.com/sample-request/industrial-laser-sensor-market/12894/

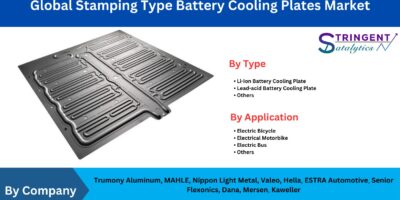

Market Segmentations:

Global Industrial Laser Sensor Market: By Company

• Banner

• Baumer

• Keyence

• Laser Technology

• Schmitt Industries

• SICK

• OMRON

• Panasonic

• Cognex

• Micro-Epsilon

• Rockwell Automation

• Wenglor

Global Industrial Laser Sensor Market: By Type

• Compact

• Ultra-compact

Global Industrial Laser Sensor Market: By Application

• Automotive

• Electronics and Semiconductors

• Packaging

• Medical Industries

• Others

Regional Analysis of Global Industrial Laser Sensor Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Industrial Laser Sensor market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Industrial Laser Sensor Market Research Report @ https://stringentdatalytics.com/purchase/industrial-laser-sensor-market/12894/

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Leave a Reply