Introduction

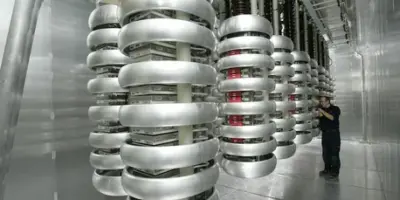

The relentless march of technological advancement hinges on the miniaturization and ever-increasing complexity of semiconductor chips. These intricate marvels of engineering form the backbone of modern electronics, powering everything from smartphones and computers to medical devices and automobiles. As chip designs become more sophisticated, so too do the cleaning processes required for their production. This is where high purity hydrogen peroxide steps onto the stage, playing a vital role in ensuring the cleanliness and quality of semiconductor wafers, the foundation of integrated circuits.

Consumption Scope: The Cleaning Powerhouse of Chip Fabrication

High purity hydrogen peroxide, exceeding the standards of commercial grades, is an essential cleaning agent in various stages of semiconductor fabrication. Its exceptional purity minimizes contamination risks, ensuring optimal chip performance and yield. Here’s a deeper dive into its consumption scope:

- Semiconductor Wafer Cleaning: Before intricate circuits are etched onto a silicon wafer, it undergoes a rigorous cleaning process. High purity hydrogen peroxide is often used in a solution known as the RCA clean (after its developers) to remove organic contaminants, metal ions, and native oxides. These contaminants can disrupt the delicate layering process and compromise chip performance.

- Etching: During the etching process, specific materials are selectively removed from the wafer to create the intricate patterns that define the circuits. Hydrogen peroxide can be used as part of a “piranha etch” solution, a powerful mixture known for its ability to remove unwanted material with high etch rates.

- Chemical Mechanical Planarization (CMP): CMP involves smoothing and polishing the wafer surface to achieve a uniform topography. This is crucial for ensuring consistent electrical properties across the entire chip. High purity hydrogen peroxide can be used in cleaning steps before and after CMP to remove residual polishing slurry and maintain surface cleanliness.

Dynamic Demand: Fueled by Miniaturization and Industry Growth

The demand for high purity hydrogen peroxide in the semiconductor market is a direct reflection of the ever-evolving needs of the industry. Several key factors drive this dynamic demand:

- Miniaturization of Transistors: As chip designers strive to pack more transistors onto a single chip, the size of these transistors shrinks. This miniaturization necessitates even more stringent cleanliness standards. Even a miniscule level of contamination can have a significant impact on the functionality of a smaller transistor, making high purity hydrogen peroxide an essential tool.

- Exponential Growth of the Semiconductor Industry: The global demand for electronics like smartphones, laptops, and internet-of-things (IoT) devices continues to surge. This translates to a corresponding increase in semiconductor production, directly impacting the consumption of high purity hydrogen peroxide.

- Shifting to 3D Chip Architectures: The industry is increasingly exploring three-dimensional (3D) chip architectures to overcome the limitations of traditional planar designs. These 3D architectures require more complex cleaning processes with a higher emphasis on controlling contamination at various levels within the chip structure. This complexity necessitates the use of high purity hydrogen peroxide for effective cleaning.

Latest Trends and Analysis: Innovation and Sustainability Take Center Stage

The landscape of the high purity hydrogen peroxide market for semiconductors is constantly evolving. Here’s a closer look at some of the most prominent trends shaping the industry:

- Rise of Ultra High Purity (UHP) Hydrogen Peroxide: As chip designs become more intricate and contamination tolerances decrease, the demand for UHP hydrogen peroxide is on the rise. UHP hydrogen peroxide boasts even lower levels of impurities compared to electronic grade, ensuring even more rigorous cleaning.

- Focus on Environmental Sustainability: The semiconductor industry is increasingly focusing on environmentally friendly practices. Manufacturers are exploring greener methods for hydrogen peroxide production, such as the use of renewable energy sources and the development of closed-loop recycling systems for spent cleaning solutions.

- Regional Market Expansion: The Asia Pacific region, particularly countries like China, South Korea, and Taiwan, is expected to be the dominant market for high purity hydrogen peroxide due to the high concentration of leading semiconductor fabrication facilities. However, other regions like Europe and North America are also expected to witness significant growth.

Receive the FREE Sample Report of High Purity Hydrogen Peroxide for Semiconductor Market Research Insights @ https://stringentdatalytics.com/sample-request/high-purity-hydrogen-peroxide-for-semiconductor-market/9793/

Market Segmentations:

Global High Purity Hydrogen Peroxide for Semiconductor Market: By Company

• Solvay

• MGC

• Evonik

• Arkema

• Technic

• Santoku Chemical Industries

• Changchun Group

• OCI Company

• Hangzhou Jingxin Chemical

• Jingrui Chemical

• Jiangyin Jianghua Microelectronics Materials

Global High Purity Hydrogen Peroxide for Semiconductor Market: By Type

• UP (SEMI G2)

• UP-S (SEMI G3)

• UP-SS (SEMI G4)

• UP-SSS (SEMI G5)

Global High Purity Hydrogen Peroxide for Semiconductor Market: By Application

• Cleaning

• Etching

Regional Analysis of Global High Purity Hydrogen Peroxide for Semiconductor Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global High Purity Hydrogen Peroxide for Semiconductor market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase High Purity Hydrogen Peroxide for Semiconductor Market Research Report @ https://stringentdatalytics.com/purchase/high-purity-hydrogen-peroxide-for-semiconductor-market/9793/

Future Growth Study: A Promising Trajectory

Market analysts predict a robust future for the high purity hydrogen peroxide market for semiconductors. Several key factors are expected to contribute to this growth:

- Rising Investments in Semiconductor Manufacturing: Governments and private companies are increasingly investing in building and expanding semiconductor fabrication facilities to meet the growing demand for chips. This translates to a direct increase in the consumption of high purity hydrogen peroxide.

- Development of Next-Generation Chip Technologies: The continuous quest for even smaller and more powerful chips will drive innovation in cleaning techniques. High purity hydrogen peroxide is likely to remain a critical component in these advancements.

- Automation and Advanced Cleaning Techniques: The adoption of automation and advanced cleaning techniques like single-wafer processing is expected to rise. While automation can improve efficiency and consistency, it also high necessitates

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

Leave a Reply