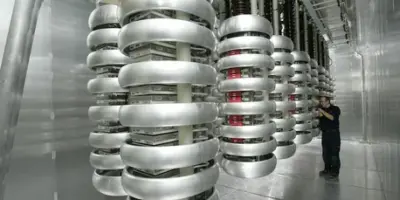

Chemical Mechanical Planarization (CMP) Retaining Rings are crucial components used in the CMP process for semiconductor manufacturing. They ensure stable positioning of wafers during polishing, contributing to the uniformity and precision required in semiconductor fabrication.

Market Overview

CMP retaining rings play a vital role in the semiconductor manufacturing process by providing mechanical support and stability to wafers during the planarization of the wafer surface. These rings help achieve uniform polishing by maintaining the correct position and pressure on the wafer.

Opportunities

- Growing Semiconductor Industry:

- Increased Chip Demand: The rising demand for advanced semiconductors for applications in electronics, automotive, AI, and IoT fuels the need for high-quality CMP retaining rings.

- Miniaturization Trends: As semiconductor devices become smaller and more complex, the precision required in CMP processes increases, driving the demand for advanced retaining rings.

- Technological Advancements:

- Innovative Materials: Development of retaining rings using advanced materials like PEEK (Polyether Ether Ketone) and other high-performance polymers enhances durability and performance.

- Customization: Advances in design and manufacturing technologies allow for custom solutions tailored to specific CMP processes and requirements, creating new market opportunities.

- Expansion in Emerging Markets:

- Semiconductor Manufacturing Growth: Expansion of semiconductor manufacturing facilities in emerging markets like China, India, and Southeast Asia presents significant opportunities for retaining ring suppliers.

- Integration with Advanced CMP Equipment:

- Enhanced Equipment Compatibility: The development of retaining rings designed to work seamlessly with the latest CMP equipment ensures better process efficiency and outcome, driving demand.

Challenges

- High Production Costs:

- Material and Manufacturing Expenses: The use of advanced materials and precision manufacturing techniques can lead to higher production costs, impacting overall profitability.

- Stringent Quality Requirements:

- Performance Standards: Meeting the high-performance and durability standards required for semiconductor fabrication can be challenging, necessitating rigorous quality control measures.

- Competitive Market Landscape:

- Price Sensitivity: Intense competition and price sensitivity in the semiconductor industry can pressure manufacturers to balance cost and quality effectively.

- Technological Barriers:

- Constant Innovation: The need for continuous innovation to keep up with advancements in semiconductor technology and CMP processes can be demanding and resource-intensive.

End-User Demand

- Semiconductor Manufacturers:

- Wafer Fabrication: CMP retaining rings are essential in achieving the flat and smooth surface required in the wafer fabrication process, ensuring the quality and performance of semiconductor devices.

- Advanced Node Technologies: The demand for retaining rings is particularly high in advanced node technologies, where precision in planarization is critical.

- Equipment Manufacturers:

- CMP Equipment: CMP retaining rings are used in various types of CMP equipment, from polishing machines to advanced planarization systems, highlighting their critical role in equipment functionality.

- Integrated Device Manufacturers (IDMs):

- In-House CMP Processes: IDMs that handle their own wafer fabrication and CMP processes require reliable and high-quality retaining rings to maintain production efficiency and product quality.

- Foundries:

- Contract Manufacturing: Semiconductor foundries providing contract manufacturing services for various clients rely on high-performance CMP retaining rings to meet diverse process requirements and maintain competitive edge.

Forecasts

- Market Growth:

- The CMP retaining rings market is expected to grow at a CAGR of approximately 4-6% from 2024 to 2030.

- The market size, valued at around USD 700 million in 2023, is projected to reach approximately USD 1.0 billion by 2030.

- Regional Outlook:

- Asia-Pacific: Anticipated to lead the market due to the concentration of semiconductor manufacturing facilities and ongoing investments in semiconductor infrastructure.

- North America: Expected to see steady growth driven by advancements in semiconductor technology and significant R&D activities.

- Europe: Moderate growth supported by increasing semiconductor manufacturing activities and technological developments.

- Industry Trends:

- Focus on Advanced Materials: Increasing use of advanced and high-performance materials for retaining rings to enhance durability and performance in CMP processes.

- Customization and Precision: Growing demand for custom-designed retaining rings to meet specific process needs and enhance CMP efficiency.

- Investment and R&D:

- Continued investment in research and development to improve retaining ring materials and design, catering to the evolving needs of advanced semiconductor manufacturing processes.

Receive the FREE Sample Report of CMP Retaining Rings Market Research Insights @ https://stringentdatalytics.com/sample-request/cmp-retaining-rings-market/9808/

Market Segmentations:

Global CMP Retaining Rings Market: By Company

• Willbe S&T

• CALITECH

• Cnus Co., Ltd.

• UIS Technologies

• Euroshore

• PTC, Inc.

• AKT Components Sdn Bhd

• Ensinger

Global CMP Retaining Rings Market: By Type

• Polyetheretherketone (PEEK)

• Polyphenylene Sulfide (PPS)

• Polyethylene Terephthalate (PET)

• Others

Global CMP Retaining Rings Market: By Application

• 300mm Wafer

• 200mm Wafer

• Others

Regional Analysis of Global CMP Retaining Rings Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global CMP Retaining Rings market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase CMP Retaining Rings Market Research Report @ https://stringentdatalytics.com/purchase/cmp-retaining-rings-market/9808/

Key Factors

- Advancements in Semiconductor Technology:

- Increased Complexity: The evolution towards smaller and more complex semiconductor nodes requires higher precision in the CMP process, driving the demand for advanced retaining rings.

- New Materials and Structures: Adoption of new semiconductor materials and 3D structures, such as FinFETs and Gate-All-Around (GAA), increases the complexity of CMP processes, necessitating enhanced retaining ring designs.

- Demand for High-Performance Materials:

- Durability and Precision: High-performance materials like PEEK, PPS (Polyphenylene Sulfide), and other advanced polymers are preferred for their durability and ability to maintain precision under rigorous CMP conditions.

- Thermal and Chemical Resistance: Retaining rings must withstand high temperatures and corrosive slurries used in CMP, making material selection crucial.

- Focus on Yield Improvement:

- Defect Reduction: Effective CMP retaining rings contribute to defect reduction during wafer polishing, enhancing yield and productivity in semiconductor manufacturing.

- Uniform Pressure Distribution: Ensuring uniform pressure distribution across the wafer surface minimizes variations and improves the overall quality of the planarization process.

- Integration with Advanced CMP Equipment:

- Compatibility: Retaining rings must be compatible with the latest CMP tools and equipment, including adaptive planarization and advanced pressure control systems.

- Automation and Precision Control: Integration with automated CMP systems and precision control mechanisms enhances process efficiency and reliability.

- Environmental and Regulatory Considerations:

- Compliance: Adhering to environmental regulations and safety standards is critical, especially concerning the materials used in retaining rings and their manufacturing processes.

- Sustainability: The shift towards more sustainable manufacturing practices drives innovation in eco-friendly materials and production methods for CMP retaining rings.

Trends

- Miniaturization and Advanced Nodes:

- Shrinking Feature Sizes: The ongoing trend towards smaller semiconductor feature sizes increases the need for more precise and reliable CMP processes, driving innovation in retaining ring technology.

- Advanced Node Adoption: Growth in the adoption of advanced nodes such as 5nm and 3nm technologies enhances the demand for high-performance retaining rings capable of meeting stringent process requirements.

- Material Innovations:

- High-Performance Polymers: Use of high-performance polymers like PEEK and PPS for retaining rings offers benefits like increased wear resistance and reduced contamination.

- Composite Materials: Development of composite materials combining polymers with ceramics or other reinforcements improves mechanical properties and extends the lifespan of retaining rings.

- Customization and Precision Engineering:

- Tailored Solutions: Growing demand for custom-engineered retaining rings tailored to specific CMP processes and equipment.

- Precision Manufacturing: Advances in precision manufacturing technologies, including CNC machining and additive manufacturing, enable the production of retaining rings with intricate designs and tight tolerances.

- Digitalization and Automation:

- Smart CMP Systems: Integration of digital technologies and automation in CMP systems enhances process control and monitoring, necessitating retaining rings compatible with these advanced systems.

- Real-Time Monitoring: Use of sensors and real-time monitoring systems to track retaining ring performance and predict maintenance needs.

Scope

- Product Range:

- Standard Retaining Rings: Widely used in conventional CMP processes for various wafer sizes and types.

- Custom Retaining Rings: Designed for specific applications and equipment, offering enhanced performance and compatibility.

- High-Performance Retaining Rings: Made from advanced materials for use in high-precision and demanding CMP processes.

- Application Areas:

- Semiconductor Fabrication: Used extensively in wafer polishing and planarization processes in semiconductor manufacturing.

- Advanced Packaging: Employed in CMP processes for advanced packaging technologies, including flip-chip and wafer-level packaging.

- Research and Development: Utilized in R&D environments for developing new semiconductor technologies and processes.

- End-User Industries:

- Integrated Device Manufacturers (IDMs): Use retaining rings in in-house wafer fabrication and CMP processes.

- Semiconductor Foundries: Employ retaining rings in contract manufacturing services for various clients.

- CMP Equipment Manufacturers: Include retaining rings as essential components in CMP systems sold to semiconductor manufacturers.

Upcoming Trends

- Enhanced Wear Resistance:

- Coating Technologies: Development of advanced coatings and surface treatments to enhance the wear resistance of retaining rings, reducing maintenance needs and extending lifespan.

- Self-Lubricating Materials: Use of self-lubricating materials to reduce friction and wear during the CMP process.

- Sustainability Focus:

- Eco-Friendly Materials: Exploration of eco-friendly materials for retaining rings to minimize environmental impact and comply with stricter environmental regulations.

- Recyclable Designs: Designing retaining rings for easier recycling and material recovery at the end of their lifecycle.

- Integration with AI and Data Analytics:

- Predictive Maintenance: Use of AI and data analytics to predict retaining ring wear and failure, enabling proactive maintenance and reducing downtime.

- Process Optimization: Leveraging data-driven insights to optimize CMP processes and enhance the performance of retaining rings.

- Collaboration and Partnerships:

- Industry Collaboration: Increased collaboration between CMP retaining ring manufacturers, semiconductor companies, and research institutions to develop next-generation solutions.

- Strategic Partnerships: Formation of strategic partnerships to enhance product development and market reach, especially in emerging markets.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Leave a Reply